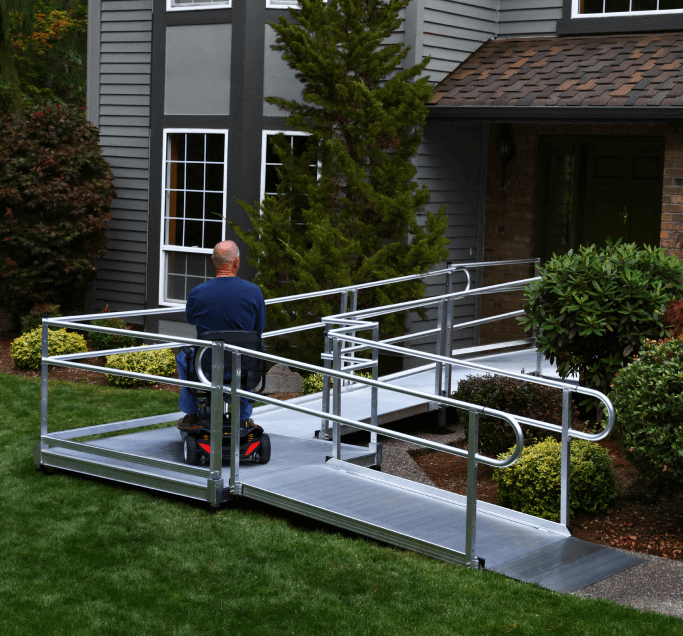

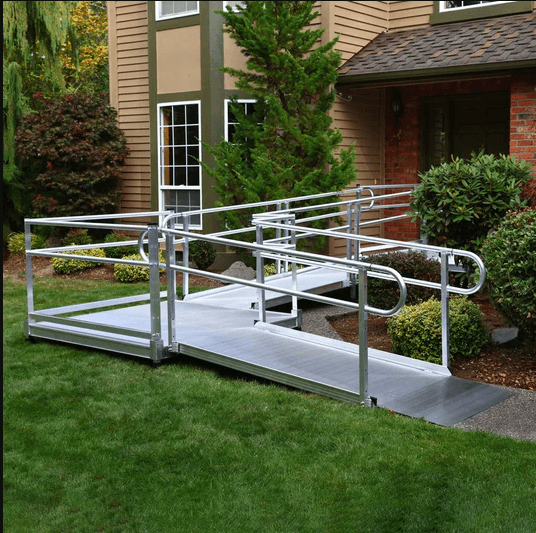

As the leaves turn vibrant shades of orange and red, and cooler breezes signal the arrival of fall, it's the perfect time to turn your attention to outdoor infrastructure—like your modular ramps. At [Your Company Name], we've seen how seasonal changes can impact accessibility solutions, and proper fall maintenance ensures your ramps remain durable, compliant, and ready for the transition into winter. Neglecting this step could lead to slippery surfaces, structural wear, or even safety hazards as rain, frost, and falling debris take their toll.In this post, we'll walk you through a simple, step-by-step guide to fall maintenance for modular ramps. Whether you're managing a commercial space, warehouse, or public facility, these tips will help you extend the life of your investment while prioritizing safety. Let's dive in!Why Fall Maintenance Matters for Modular RampsFall brings a unique mix of challenges: increased moisture from rain and morning dew, piles of wet leaves that can clog drainage, and the first hints of freeze-thaw cycles. Modular ramps, with their customizable aluminum or composite designs, are built tough—but they're not invincible. Regular upkeep prevents corrosion, maintains traction, and ensures ADA compliance. Plus, it's a proactive way to avoid costly repairs come spring.Pro tip: Schedule your fall check-up in early October, like right now (hello, October 2nd!), before the weather really turns.Step 1: Thorough Cleaning to Combat Fall DebrisLeaves, pine needles, and dirt are fall's unwelcome guests. A clean ramp is a safe ramp.

- Sweep and Hose Down: Start with a stiff broom to remove loose debris. Follow up with a pressure washer (low PSI to avoid damaging surfaces) and mild soap. Focus on joints and edges where grime hides.

- Clear Drainage Paths: Modular ramps often have built-in channels—ensure they're free of blockages to prevent pooling water, which can lead to ice in colder months.

- Eco-Friendly Tip: Use biodegradable cleaners to keep your maintenance green, aligning with sustainable business practices.

Aim to do this bi-weekly through November to stay ahead of the leaf drop.Step 2: Inspect for Wear and TearVisual checks are your first line of defense against bigger issues.

- Surface Traction: Test for slipperiness by walking the ramp in wet conditions. If needed, reapply anti-slip coatings or textured overlays—our modular systems come with options for enhanced grip.

- Structural Integrity: Look for loose bolts, bent rails, or cracks in the framework. Tighten fasteners and note any damage for professional review.

- Handrails and Edges: Ensure handrails are secure and free of rust. Fall winds can loosen connections, so give them a good shake test.

Document everything with photos—it's great for warranty claims and tracking long-term performance.Step 3: Weatherproofing for the Seasons Ahead Fall is your buffer zone before winter hits, so fortify now.

- Seal and Protect: Apply a UV-resistant sealant to exposed metal parts to fend off rust from autumn rains. For composite materials, a simple wax polish keeps them looking new.

- Winter Prep Lite: While full snow removal gear comes later, install temporary wind barriers if your ramps face high-traffic gusty areas.

- Lighting Check: With shorter days, verify that any integrated LED lights are functioning. Good visibility reduces accidents as dusk arrives earlier.

Our team recommends annual professional audits, but these DIY steps can bridge the gap.